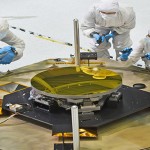

The sole secondary mirror and another primary mirror that will fly aboard NASA’s James Webb Space Telescope arrived at NASA’s Goddard Space Flight Center in Greenbelt, Md., on Nov. 5, 2012. In this photo, technicians inspect the secondary mirror using flashlights. Reflections of one of the technicians and the roof of the giant clean room that houses the mirror are seen on the mirror’s surface.

Unlike the 18 hexagonal primary segments that make up the biggest mirror on the Webb telescope, the secondary mirror is perfectly rounded. The mirror is also convex, so the reflective surface bulges toward a light source. It looks much like the curved mirrors on the walls near parking garage exits that let motorists see around corners.

The mirror is made of beryllium, which was selected for its stiffness, light weight and stability at cryogenic temperatures. Bare beryllium is not very reflective of near-infrared light, so each mirror is coated with gold. The microscopic gold coating enables the secondary mirror to efficiently reflect infrared light (which is what the Webb telescope’s cameras see). The quality of the secondary mirror surface is so good that the final convex surface at cold temperatures does not deviate from the design by more than a few millionths of a millimeter — or about one ten-thousandth the diameter of a human hair.

Previously on Sept. 17, 2012, two other primary mirror segments arrived at NASA Goddard and are currently being stored in the giant clean room on campus. Ball Aerospace & Technologies Corp. of Boulder, Colo., manufactured, packed and shipped the mirrors to NASA Goddard.

The most powerful space telescope ever built, the Webb telescope will provide images of the first galaxies ever formed and study planets around distant stars. It is a joint project of NASA, the European Space Agency and the Canadian Space Agency.

English

English  Français

Français  العربية

العربية